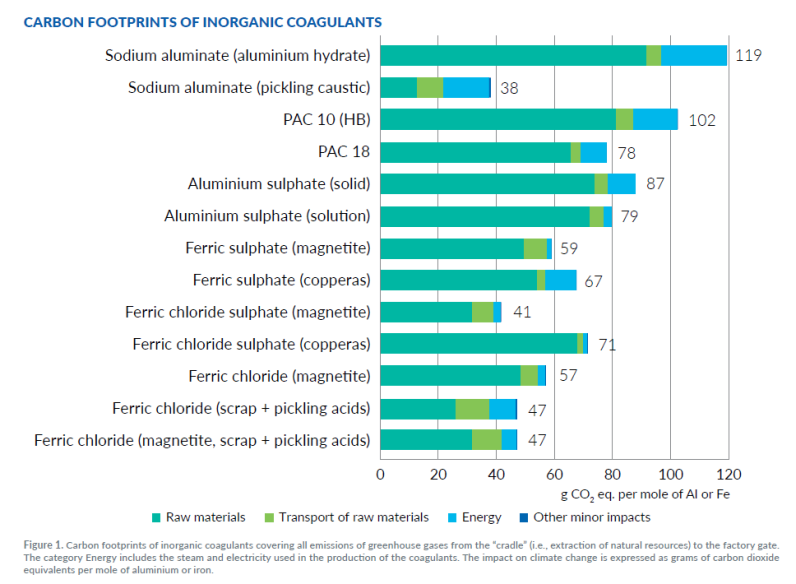

Coagulants using hydrochloric acid have resulted in notably lower carbon footprints

The aim of the latest study carried out by INCOPA was to calculate the carbon footprints of inorganic coagulants produced by its member companies, one of which is Kuhlmann Europe.

According to the findings presented in the study, the primary contributor to the climate change impact during coagulant creation is the production of raw materials. Therefore, it is considered by experts more important to choose suppliers based on their environmental performance given the fact that incorporating secondary raw materials into the production process can significantly reduce the carbon footprints of inorganic coagulants.

This latest study has revealed that coagulants using hydrochloric acid have resulted in notably lower carbon footprints compared to the study undertaken in 2014.

At Kuhlmann Europe, we play a significant role in the production of ferric chloride. Our operations are spread across multiple sites and we use a wide variety of raw materials. Furthermore, our circular business model for water treatment products enables us to repurpose the hydrochloric acid by-product from our fertilizer production as a raw material for the steel industry.

Targeting iron oxide removal from sheet and coil surfaces generates iron-containing spent acid solutions in the pickling lines. These co-products are subsequently utilized as secondary raw materials in several of our ferric chloride manufacturing facilities across Europe.

By valorizing these co-products, we not only contribute to resource preservation, including iron ore (magnetite), but also produce a crucial element for wastewater treatment, thereby safeguarding the environment.

Consult the full study here